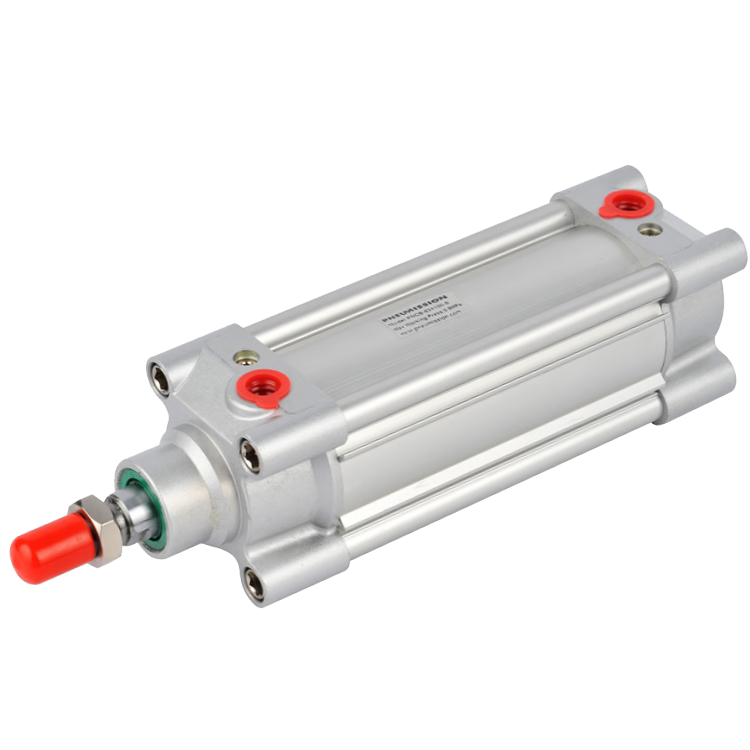

Cylinders

Air Cylinder is the word for a mechanical device that moves linear driven by air pressure.

The inside of the pneumatic cylinder is round so the sealing between the moving part, the piston, and the cylinder tube can be done sufficient. Attached to the piston is the piston-rod that sticks out of the cylinder through the " nose". In this nose are 2 seals; 1 for keeping the air inside and 1 for keeping the dirt outside. Between them there is a guide bushing. If there is a pressure at 1 side of the piston and no pressure at the other side, the piston will move and the piston-rod will move. That is way they are also called pneumatic actuators.

This is a simple and easy way to make a pneumatic movement, only air pressure is needed. This is clean and not as dangerous as hydraulics.

Before 1985 every pneumatic factory made the cylinders according to their own dimensions.

For example the British producers made them with INCH sizes. They were the first to produce air cylinders because the UK was the leader country in the Steam Driven automation. Pneumatic linear actuators comes from steam driven cylinders.

The heritage of the INCH sizes is still to be found in the size of the diameters.

25, 32, 40, 50 63 and 80 are all coming from the early days that Inch sizes were used.

The well know SM900 series from Martonair had the diameter in the code number.

The disadvantage of the fact that every pneumatic brand used their own dimensions was that if a cylinder needed to be replaced that it could only be done be a cylinder of exactly the same brand.

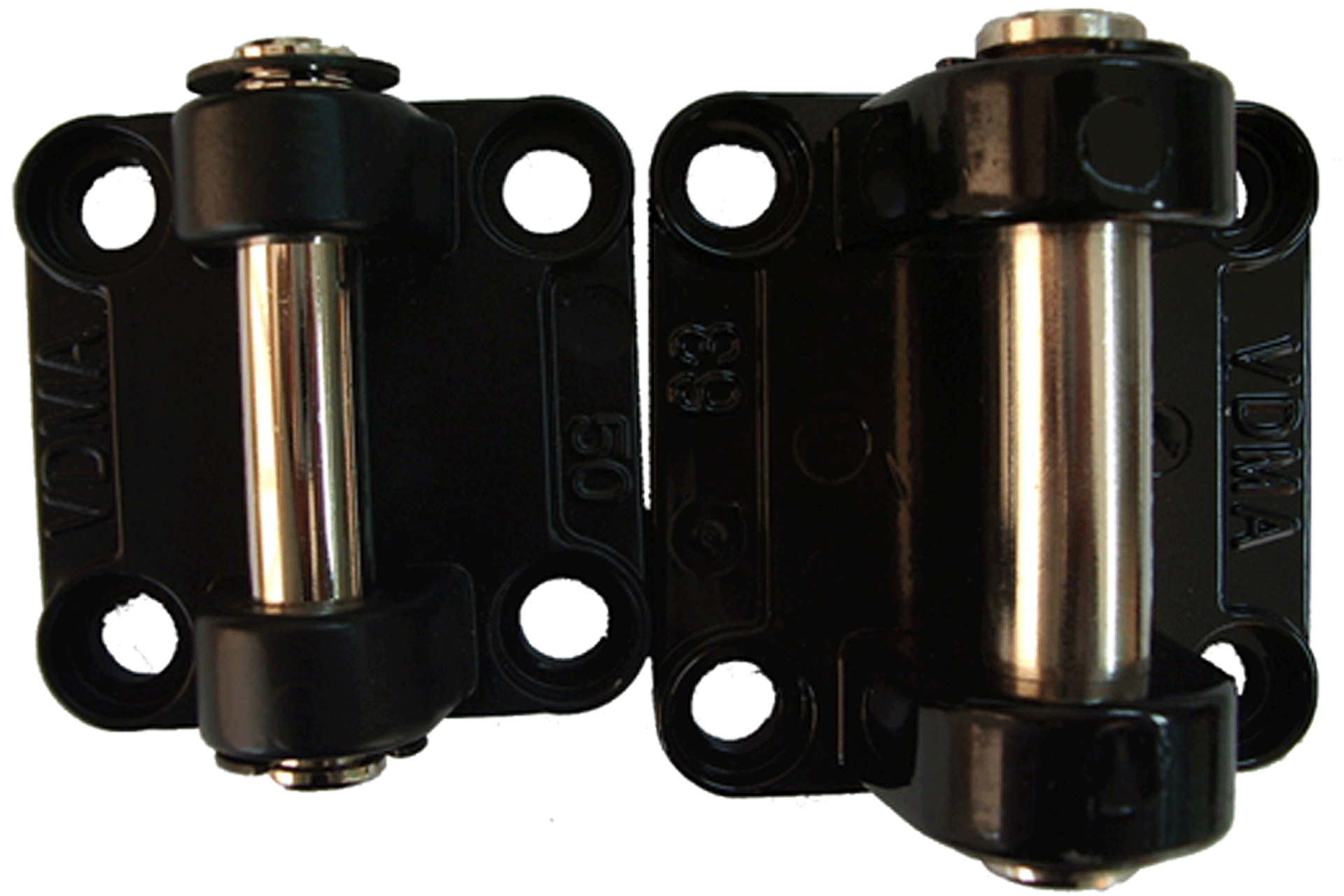

Firstly Cetop and later also the ISO standard commission made the ISO 6431 standard for pneumatic cylinders. A cylinder according to this Standard can be replaced with any other cylinder with that ISO standard.

This is for the European market and more and more for the Asian market.

For the USA the NFPA standard is still commonly used.

South America is a mix of ISO and NFPA.

Today most pneumatic actuators are according to the ISO 15552 that is valid since 2015.

Even the compact cylinder have an ISO standard today.

If there are any questions about dimensions and standard, you can always contact our engineers.